Computerized ICE plant trainer

Product Details:

Computerized ICE plant trainer Price And Quantity

- 01 Piece

- 406215 INR/Piece

Product Description

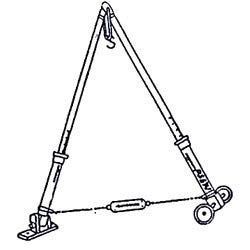

Total Equipment isskid mounted in SS 40 x40 Frame Structure with Castor wheels. All wetted partsalso made of SS-304 \

Compressor-Hermiticallysealed compressor, Kirloskar make. Tank: The inner tank shall be fabricated outof stainless steel Condenser:

Air cooledcompatible to compressor Condenser Cooling Fan: Compatible capacity withpermanent lubricated motor. \

PressureMeasurement: Pressure Transmitter- 2 Nos.

TemperatureMeasurement: Temperature Transmitter- 6 Nos.

Evaporator: Made ofStainless Steel, Insulated with ceramic wool/puff.

Expansion Device:Capillary Tube Compatible capacity.

Energy Measurement:By Energy meter

Safety Control:overload and over current protectors for compressor and Time delay circuit.

Measuring ranges

Differentialpressure: 0-1000Pa (air)

Flow rate: 12-360L/h(water)

Temperature: 2x0-50C, 3x 0-100C

Rel. humidity:10-100%

Required foroperation

230V, 50Hz, 1 phase

Touch screen basedFully automatic system with password protection Data acquisition should beRemotely operated by Smart phone, Tablets, PC, laptops via Ethernet and Wi-fiShould be equipped with all safety protections Flow visualization should beavailable in the DAQ System

Should be equippedwith both manual and auto operation Power consumption of individual system, allsensorsï data should be display and logged automatically System should havesoftware for operating, data logging, processing and data displaying

Performancevariables (e.g., Heating/Cooling COP, Heating / Cooling load etc..)

should beautomatically calculated and displayed and should be stored in pen drive alsoalong with PC. Instruments should be provided with 3D drawing of completeequipment along with the

name and make of all standard components used inthe test rig Each rig should have small aesthetically appealing poster withschematic diagram and basic working detail.Other Products in 'Mechanical Engineering Laboratory Equipment' category

|

D.D.R. INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry