Computerized Mechanical Heat Pump Test Rig

Product Details:

Computerized Mechanical Heat Pump Test Rig Price And Quantity

- 597375 INR/Piece

- 01 Piece

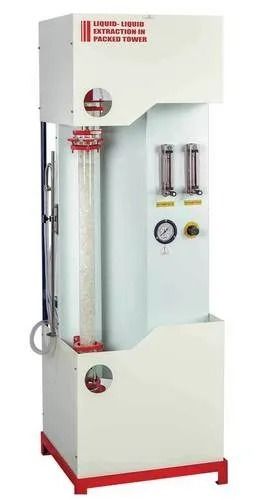

Product Description

Heat pump operationmanagement controller supplied with programming software and cable. The programis provided on computerised DAQ. Sensor Set to include

1) Thermocoupletemperature sensor for measuring temperature in particular:-

a) Compressor input

b) Compressor output

c) Reducer inlet

d) Water inletexchanger

e) Water outletexchanger

2) 2 analog pressuretransmitters (high and low pressure)

3) 1 water flowmeter on the impulse output condenser All the data of temperature, pressure andflow, as well as the power consumed, the power restored and the efficiency ofthe pump can be visualized on the panel display.

Total Equipment isskid mounted in SS 40 x40 Frame Structure with Castor

wheels. All wettedparts also made of SS-304

Compressor Capacity:372W at 7,2/32C Coaxial coil heat exchanger (condenser) Refrigerant content:0,55L

Water content: 0,3L

Finned tubeevaporator Transfer area: approx. 0,175m2

Pump

Max. Flow rate:1,9m3/h

Max. Head: 1,4m

Hot water tankvolume: approx. 4,5L Refrigerant: R134a/22/A

Filling volume: 1kg

CO2-equivalent: 0,6t

Measuring ranges

Pressure: 2x-1-15bar

Temperature: 4x0-100C, 2x -100-100C Power: 0-6000W

Flow rate: 0-108L/h(water)

Flow rate: 10-160L/h(cooling water) Required for operation

230V, 50Hz, 1 phase

Touch screen basedFully automatic system with password protection

Data acquisitionshould be Remotely operated by Smart phone, Tablets, PC, laptops via Ethernetand Wi-fi Should be equipped with all safety protections Flow visualizationshould be available in the DAQ System

Should be equippedwith both manual and auto operation

Power consumption ofindividual system, all sensors™ data should be display and logged automatically

System should havesoftware for operating, data logging, processing and data displaying

Performancevariables (e.g., Heating/Cooling COP, Heating / Cooling load etc.)

should beautomatically calculated and displayed and should be stored in pen drive alsoalong with PC.

Instruments shouldbe provided with 3D drawing of complete equipment along with the name and makeof all standard components used in the test rig

Each rig should havesmall aesthetically appealing poster with schematic diagram and basic workingdetail

Other Products in 'Mechanical Engineering Laboratory Equipment' category

|

D.D.R. INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry